Micro-Factories: A Game-Changer in Sustainable Manufacturing

Written on

Chapter 1: Understanding Micro-Factories

In recent times, the rise of micro-factories has gained significant attention, making it a topic that warrants thorough exploration.

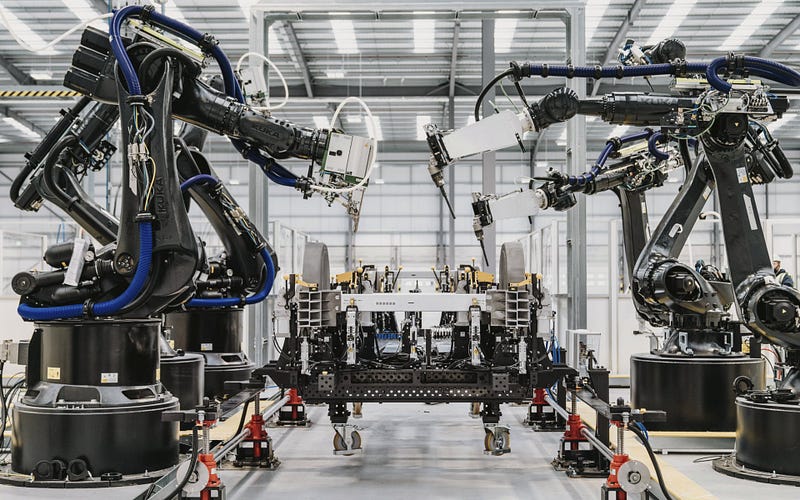

Photo Credit: ARRIVAL | THE MICROFACTORY

At its core, a micro-factory is a compact manufacturing unit that can fit within a single shipping container. This innovative approach allows for the production of goods and services in a manner that is both efficient and environmentally friendly.

Looking back, the origins of this concept trace back to Japan in the early 2000s, and it has since seen global adaptation.

Exploring the range of products typically manufactured in these small-scale facilities reveals a diverse assortment, including:

- An array of 3D-printed items;

- Apparel such as t-shirts, jeans, jackets, and footwear;

- Jewelry like rings, necklaces, and bracelets;

- Industrial components such as valves, pumps, and engines;

- A variety of food items, including snacks, cereals, yogurts, and ready-to-eat meals.

For non-food products, the creation process generally commences with the design phase, followed by the production of components via 3D printers or CNC machines. However, a closer look at food production in micro-factories warrants special attention.

Section 1.1: Food Production in Micro-Factories

The journey of food production in micro-factories starts with sourcing ingredients from local suppliers, chosen meticulously to ensure quality standards are met. Once prepared, these ingredients undergo processing with specialized equipment, such as blending machines, homogenizers, and extruders. Subsequently, the finished products are packaged and dispatched to customers.

Additionally, containers can be utilized to transport fresh produce from farms to markets, ensuring quality and safety upon arrival.

Subsection 1.1.1: Enhancing Food Security

The micro-factory model holds particular significance in the food sector, where it can bolster food security in both affluent and developing nations. This model aims to alleviate the environmental consequences tied to food production. By leveraging renewable energy and sustainable practices, micro-factories reduce emissions and waste in their operations.

Section 1.2: Flexibility and Rapid Deployment

One of the standout benefits of this innovative technology is its adaptability for various applications. It proves to be a vital solution in challenging environments, such as conflict zones or areas where quick returns on investment are crucial, like parts of Africa. The charm of micro-factories lies in their ability to be established or decommissioned within hours, typically requiring only connections to water and electricity. This makes them ideal for locations needing swift and effective solutions.

Moreover, these containers can serve as storage for food supplies during emergencies, providing immediate access during crises.

Chapter 2: The Future of Micro-Factories

I have delved into numerous aspects highlighting the advantages of implementing micro-factories. Ultimately, it is evident that this innovative and adaptable solution can significantly impact various sectors. Embracing this technology could empower humanity to tackle pressing challenges while paving the way for a more secure and sustainable future for everyone.

The video titled "Big Techday 23: Taming the Home Connect Microservice Jungle [EN] - T. Richer, BSH & T. Masur, TNG - YouTube" provides further insights into modern technological adaptations and their implications for various industries.